Home >> Technology >> Aging system design

Why do we need light stabilizers?

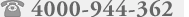

Adversely affect the life of the sun and some artificial illumination will polymer materials. This adverse effect is usually manifested in fading, surface cracking, loss of light, tensile strength, elongation at break and a series of changes in the mechanical properties decrease. This is due to UV radiation can lead to polymer bond Duan Li, causing serious degradation of light, which led to the loss of the physical properties of the material. Plough is committed to providing customers with a complete solution for light stabilizers, UV stabilizers and offer a range of products, polyolefin, a variety of plastic materials and coatings, usually just add a few thousandths, can effectively alleviate photochemical reaction, greatly extend the life of polymer materials.

A wide range of light stabilizer additives, briefly speaking, can be divided into two categories, namely UV Absorbers (UV Absorber, UVA) and hindered amine light stabilizers (Hindered Amine Light Stabilizer, HALS).

UV Absorbers,UVA

UV absorbers by absorbing UV radiation in the part of a polymer material, and the harmful UV radiation into harmless heat energy to avoid material losses, and is one of many commonly used in engineering plastics and paint shine aging means . To achieve this performance, an ultraviolet absorber generally requires a certain concentration of the material surface, and has a certain thickness can play a better effect. In many applications, an ultraviolet absorber and a hindered amine light stabilizer used in conjunction to significantly improve the light stability performance.

Hindered Amine Light Stabilizers,HALS

Hindered amine light stabilizer does not absorb ultraviolet light, but it is very effective UV stabilizers. Such additives have a hindered amine group activity, photodegradation chain reaction of free radicals produced by capturing, effective to suppress the light degradation of chemical reactions. Such light stabilizers can achieve excellent anti-aging effects at lower concentrations, this high-performance part from its molecular structure recycled ability nitroxides. Since no work is dependent on the thickness of the article, HALS products on the surface of thin and thick products can provide a more prominent protection. Many hindered amine light stabilizer is also the case of room temperature to higher temperatures, long-term use of thermal stabilizers, can significantly improve long-term thermal stability of the article (Long-term Heat Stability, LTHS). Moreover, the relatively high demand in many chemical fiber industry, such as polypropylene, polyurethane, nylon, etc., hindered amine light stabilizer is also used as an alternative to fiber polymerization of phenolic antioxidants in the production process to use the main antioxidant.

A wide range of light stabilizer additives, briefly speaking, can be divided into two categories, namely UV Absorbers (UV Absorber, UVA) and hindered amine light stabilizers (Hindered Amine Light Stabilizer, HALS).

UV Absorbers,UVA

UV absorbers by absorbing UV radiation in the part of a polymer material, and the harmful UV radiation into harmless heat energy to avoid material losses, and is one of many commonly used in engineering plastics and paint shine aging means . To achieve this performance, an ultraviolet absorber generally requires a certain concentration of the material surface, and has a certain thickness can play a better effect. In many applications, an ultraviolet absorber and a hindered amine light stabilizer used in conjunction to significantly improve the light stability performance.

Hindered Amine Light Stabilizers,HALS

Hindered amine light stabilizer does not absorb ultraviolet light, but it is very effective UV stabilizers. Such additives have a hindered amine group activity, photodegradation chain reaction of free radicals produced by capturing, effective to suppress the light degradation of chemical reactions. Such light stabilizers can achieve excellent anti-aging effects at lower concentrations, this high-performance part from its molecular structure recycled ability nitroxides. Since no work is dependent on the thickness of the article, HALS products on the surface of thin and thick products can provide a more prominent protection. Many hindered amine light stabilizer is also the case of room temperature to higher temperatures, long-term use of thermal stabilizers, can significantly improve long-term thermal stability of the article (Long-term Heat Stability, LTHS). Moreover, the relatively high demand in many chemical fiber industry, such as polypropylene, polyurethane, nylon, etc., hindered amine light stabilizer is also used as an alternative to fiber polymerization of phenolic antioxidants in the production process to use the main antioxidant.

Light Stabilizer for Plastics

Light Stabilizer for Coatings